The World’s Safest Lead Acid (Car) Battery Container

UNISEG’s Battery Transport & Storage (BTS) Container was specifically designed for the safe, environmentally sustainable and efficient storage and transportation of used car batteries and other lead acid batteries. The BTS Container eliminates many of the short comings of the current methods used to store and transport lead acid batteries and was shortlisted in April 2018 for the Battery Council International’s Innovation Award.

There are numerous plastic containers available for the storage and transport of used lead acid batteries, so why do we claim the BTS Container to be the world’s safest container?

- The BTS Container includes a unique front loading feature for the ergonomically safe loading of batteries.

- At 95kg the BTS has been manufactured to deliver the most rugged, toughest container available for the safe transport of batteries. Features include;

- The BTS is manufactured using rota moulded Low Density Polyethylene (LDPE), which is incredibly long lasting and durable. As well as being UV Resistant & Acid Proof, LDPE is less prone to shattering compared to plastic injected containers. With normal use we anticipate the BTS Containers lasting 10 – 15 years and possibly longer.

- The 4 hinges that join each panel are made from 8mm 304 Stainless Steel Rods.

- The 6 stainless steel, self closing over-centre latches, for securing the containers, use a proprietary and patented self closing latch – the Snap-Flat latch. Each Snap-Flat latch has a breaking strain in excess of 1 Tonne.

The safety features and environmental benefits of the BTS Container has seen many mining companies such as BHP & Rio Tinto adopt the container for the storage and offsite transport of used lead acid batteries from their mine sites.

The BTS Container has been “road tested” since 2015 by our sister company, Battery Rescue, which provides a battery collection service to Western Australian businesses. In this time, none of the more than 250 containers deployed have been replaced, with only minor hardware repairs required.

As A Lead Acid Battery Storage Container

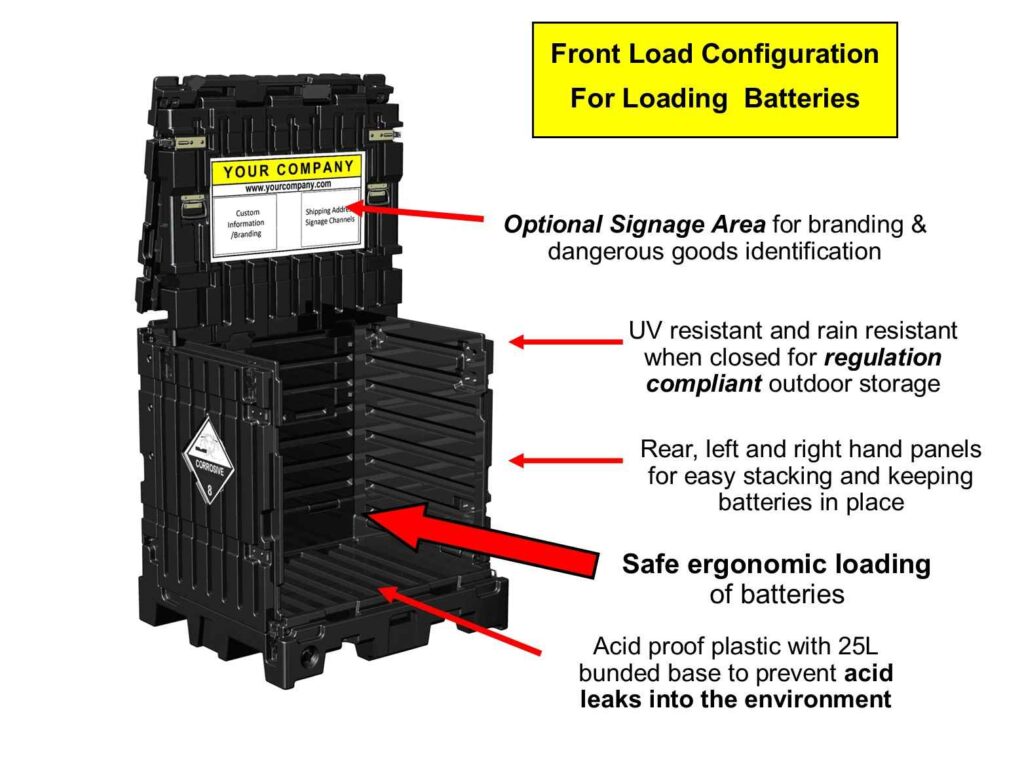

The figure below shows UNISEG’s BTS Container in the front load configuration and its features that make it ideal as a used car battery storage container and lead acid battery container;

Note:

When using the BTS Container outdoors, it is recommended that it is kept close (as pictured below) to prevent it filling with rainwater.

The lockable over-center latches can secure the used car batteries against theft.

As A Lead Acid Battery Transport Container

The figure below shows UNISEG’s Battery Transport & Storage Container, closed and ready for the immediate, safe & secure transport of your used car batteries and other lead acid batteries.

For efficient reverse logistics, the BTS Container can be collapsed and stacked up to 4 units high.

BTS Container Configurations

Benefit’s Of UNISEG’s Battery Transport & Storage Container

The major benefits of the BTS Container for the storage and transportation of used lead acid batteries (ULAB), include;

1. Eliminates Double and Manual Handling of Used Batteries

The BTS Container is designed for used lead acid batteries to be collected from the “coal face”, the Used Battery Generators, and be delivered directly to the Battery Recycling Facilities, where the used batteries can be automatically unloaded. From the point of storage to the battery recycler, there is no manual handling of batteries required .

2. Safe, Convenient & Environmentally Sustainable Used Battery Storage

The Battery Container’s front load configuration enables the ergonomic loading of heavy car batteries into the Battery Container. The 25 litre bunded base captures and prevents acid leaks into the environment and the weather resistant design enables batteries to be stored outdoor. The BTS Container also provides a convenient & clearly identified location for used lead acid battery storage.

3. Safe, Convenient & Environmentally Sustainable Used Battery Transportation

The BTS is better suited for transporting used lead acid batteries than the commonly used wood pallet. Its bunded base ensures any acid leaks are contained during transport. When secured by the 6 stainless steel over center latches, it is incredibly strong and the load of heavy batteries very secure. When full the Battery Container can be closed and ready for transport in less than 30 seconds.

4. Regulation Compliance & Chain of Responsibility

Used lead acid batteries are a Controlled Hazardous Waste and a designated Dangerous Good and as such must be stored, handled, transported and recycled in accordance with Environmental, Dangerous Goods and Workplace Health and Safety regulations.

The Battery Transport & Storage Container, helps companies comply with the various regulations governing the storage and transportation of lead acid batteries. And thereby meet their “duty of care” and “chain of responsibility” requirements.

The UN Sub-Committee of Experts on the Transport of Dangerous Goods approved in June 2018 new lead acid battery transport regulations, with these changes expected to be adopted in most countries’ dangerous goods regulations.

BTS Container Specifications

- For further details regarding the signage options for the BTS Container, go to Signage Options.

- The standard Container is all black. For further details regarding alternative colour options for the BTS Container see Branding Options.

Instructions For Using The BTS Container

Follow the this link for important safety messages and instructions on how to operate the BTS Container.

For information on how to safely stack and store used lead acid batteries in the BTS Container so as to reduce their fire risks, see “Battery Safety – Reducing Their Fire Risk“

Lead Acid Battery Storage & Transport Regulations

Lead acid batteries are classified as a dangerous good and used or waste lead acid batteries are also classified as a hazardous waste. As a result their storage and transportation is controlled by several different regulations.

You can find here, a summary of the Australian storage and transport regulations for lead acid batteries.

The BTS Container was purposely designed to help companies achieve regulation compliance.

Developing a Battery Collection Service Using the BTS Container

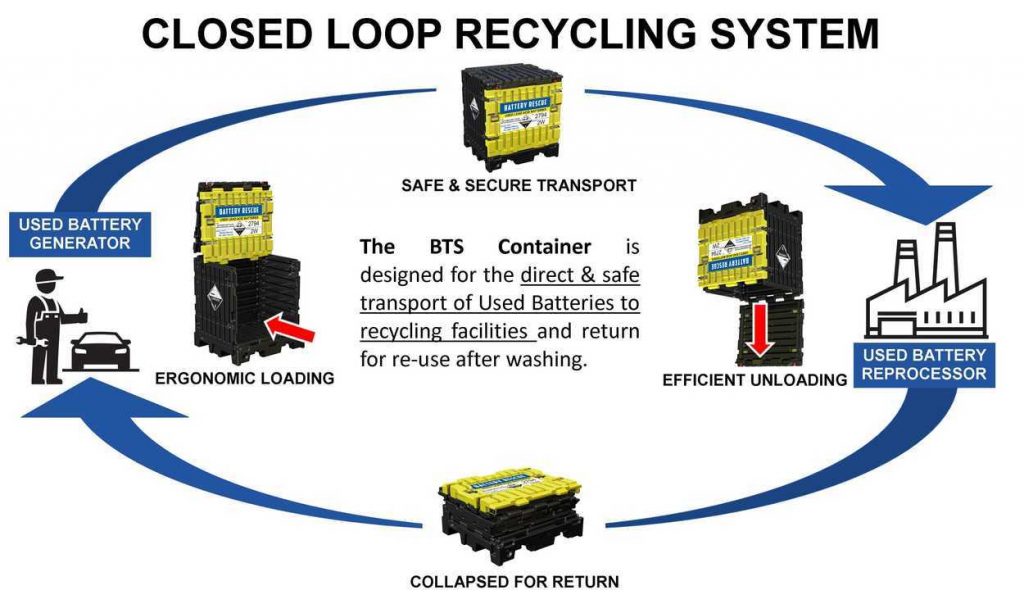

Customers wanting to deliver used batteries directly to a Battery Reprocessor using the Battery Transport & Storage Container, will need to operate a closed loop container system (see figure below). This is a fundamental and significant difference compared to using wood pallets, which are usually delivered one way.

The closed loop container system requires that the Battery Containers, after being emptied at the reprocessing plants (and washed clean of any acid and dirt by the plant), are collapsed and returned to the Battery Collector / Scrap Metal Company (SMD) for re-deployment with their customers (used battery generators).

Operating a Closed Loop Battery Recycling System

The basic steps to operating the battery container pooling system, are:

- The Battery Containers are initially deployed at customer sites (used battery generators), by the Battery Collector / SMD.

- When full the Battery Collector will deliver an empty exchange BTS Container simultaneously picking up the full Container. The full BTS Containers are consolidated by the Collector before being shipped, in quantities of 20, to the Battery Reprocessor.

- The Battery Processing Plant will then decant and wash the Container before stockpiling the empty units ready for return.

- When there are sufficient empty BTS Containers at the Battery Processing Plant, the Battery Collector will arrange for their collection.

- The BTS Containers are redeployed at the Battery Collector’s customer sites.

To operate a closed loop system, generally requires a reasonable quantity of Battery Containers, to minimise the transportation costs. A shipment of 20 full BTS Containers and return shipment of 20 empty, collapsed Containers, is recommended. For smaller quantities it might be better to deliver the Battery Container to a local Battery Collector who can unload the batteries and pack them onto a wood pallet, for delivery to the Reprocessor.

Economics of a Closed Loop System

An independent costing by Kevin Jones, Director of Fleetrak Consulting (formerly the International Business Development Manager for Chep Pallecon Solutions APAC), demonstrated that despite the additional costs of washing and returning the BTS Containers within Australia, that on average there is a saving of $21 per tonne of batteries transported using the BTS Container versus wood pallets. The savings are due to the time and materials involved in preparing the batteries for transport on wood pallets and the efficiency gains of automatic unloading from the BTS Container. Fleetrak’s costing can be provided upon request.

‘Proof of Concept’ Used Car Battery / Lead Acid Battery Collection System

UNISEG Product’s established Battery Rescue www.batteryrescue.com.au, to demonstrate the benefits and viability of a lead acid battery collection service, using the BTS Container. Battery Rescue has deployed in excess of 250 BTS containers with over 60 customers, including automotive workshops, transport companies, government waste facilities, marine & aircraft facilities, equipment hire and mining companies. Batteries collected mainly include car batteries and other automotive application but also include lead acid batteries used for solar, UPS and other industrial applications.

The popularity of this service and the BTS Containers is growing every year.

White Paper – Creating A Safer, Environmentally Sustainable Lead Acid Battery Recycling Industry

Why Wood Pallets Shouldn’t Be Used For Transporting Lead Acid Batteries?

The default device for transporting used lead acid batteries (ULAB) in most countries throughout the world, is the wood pallet. It is popular due to its low cost, widespread availability and the convenience of being able to transport one way. The wood pallet however has a number of significant drawbacks for transporting ULABs, including;

- Acid leaks during storage and transportation are not contained posing threats to human health and the environment. The sulfuric acid electrolyte in wet lead acid batteries, such as most car batteries, contains high levels of toxic lead and other heavy metals. Lead has been identified by the World Health Organisation (WHO) as one of the 10 chemicals of major public health concern. WHO currently suggest there are no known levels of lead exposure that are considered safe. The acidic electrolyte can also result in burn injuries, damage to property and the environment.

- Poor, non-compliant packaging and load restraint due to;

- Variations in the worker’s attitude and training.

- Packaging of batteries on pallets is time consuming, difficult and unsafe.

- Required materials & tools not available (good quality wood pallets, plastic wrap, strapping tool, 30mm card separators).

- Use of cheap, poor quality wood pallets (due to availability and cost saving).

- Batteries of many different sizes are difficult to stack securely on pallets.

- Disposal to landfill of packaging materials, including cardboard separators, plastic wrapping, strapping and wood pallets damaged or contaminated with battery acid.

BTS Containers vs Heavy Duty Non-Collapsible Bins

Non Collapsible, Heavy duty plastic bins are growing in popularity and are commonly used by the European battery recycling industry. See the following for a comparison of the BTS versus Plastic Battery Bins.